Wuxi Sicote Power Technology CO., Ltd. produce 20KW Parking Take-off Generator Set (Single Phase);

驻车取力发电装置,就是当载车停下后,利用汽车底盘上取力口,通过传动轴等传动装置驱动发电机发电的装置。底盘柴油机是取力发电装置的动力源,取力发电装置输出交流电的频率指标通过电子调速器对底盘柴油机的调速控制实现。

取力发电装置中底盘柴油机除了为取力发电装置提供动力外,还为汽车行驶提供动力,为满足汽车行驶性能要求,柴油机的转速调速率一般都较大,不利于取力发电装置输出交流电的技术指标实现;柴油发电机组中柴油机只为发电机组提供动力输出,为保证发电机组的输出交流电技术指标,一般都要求柴油机的转速调速率较小。其次,取力发电装置中柴油机飞轮转动惯量较小,不利于柴油机转速的稳定控制;而在柴油发电机组中通常都是选用较大转动惯量的飞轮来保证柴油机转速稳定运行。

另外,柴油发电机组可以将柴油机、发电机等集成于专用底架上,柴油机运行产生的振动、噪声等可以通过减震、降噪等措施适当削弱,这也有利于柴油机的平稳运行和转速控制;而取力发电装置的动力源为底盘柴油机,柴油机按照底盘需求进行安装固定,柴油机运行产生的振动、噪声等不利影响一般不易通过额外的减震、降噪措施来削弱,工程应用时一般只有通过降低柴油机转速来实现,而柴油机转速的降低将导致取力发电装置输出交流电技术指标的实现更加困难。另外,取力发电装置的油门控制机构和汽车底盘的脚踏油门机构均与底盘柴油机油门摆臂连接,如果取力发电装置的油门控制机构设计不合理,容易与脚踏油门机构干涉,不利于柴油机转速的稳定控制;柴油发电机组中油门摆臂只用于发电控制用,不会产生干涉问题,利于柴油机转速的稳定控制。

综上所述,取力发电装置的柴油机转速控制受到汽车底盘固有行驶特性需求的影响,柴油机转速控制在技术实现上与一般的柴油机组具有较大的区别,要达到柴油发电机组的性能指标要求,技术实现难度很大,要克服的不利因素很多,要实现柴油机转速的理想控制,在控制方法上就要针对诸多不利影响因素,采取有效控制策略和措施达到理想控制柴油机转速的目的。

4.1 主要技术要求

(1) 输出功率≥20kW(带负载输出/1500rpm);

(2) 最大输出功率22kW;

(3) 输出220V的交流电;

(4) 最大额定电流100A;

(5) 驻车提速使用按键提速,提速开关可根据需要安装于任何位置或做成无线控制;(底盘出厂刷好程序可取消)

(6) 配电柜尺寸见附图,只显示三相电压与单相电压;

(7) 外观质量:外观应整洁、美观,无锈蚀、涂层脱落、气泡、裂纹和凹凸不平等现象;

4.2 安装方式

取力发电机安装与车辆底盘上,通过改装专用的传动装置进行传动,调速装置安装于驾驶室下,调速按钮安装于驾驶室驾驶员一侧或者采用无线控制;

为了便于安装,安装须在底盘上装前完成;

5 通用质量特性要求

5.1 环境适应性

(1) 工作环境温度:-25℃~+46℃;

(2) 贮存极限温度:-40℃~+65℃;

(3) 最大海拔高度:≥4000m;

(4) 振动:应能承受运输过程中的振动载荷,满足GJB 150.16A-2009《军用装备实验室环境试验方法第16部分:振动试验》规定的图C.3轮式车辆运输振动载荷要求;

(5) 湿热:工作条件93%(35℃);承受条件93%(40℃);

(6) 抗淋雨能力:能承受降雨强度0.8mm/min;

(7) 防护等级:IP57;

5.2 可靠性

(1)遵循GJB 450A-2004《装备可靠性工作通用要求》相关要求;

(2)系统平均无故障工作时间(MTBF):最低可接受值50小时。

5.3 维修性

(1)遵循GJB 368B-2009《装备维修性工作通用要求》。

(2)系统组成模块化,以换件维修为主,平均修复时间(MTTR)小于等于0.5小时

5.4 测试性

(1)系统测试性要求符合GJB 2547A-2012《装备测试性工作通用要求》的相关规定;

(2)系统具备自检测功能,预留外接检测与调试接口。

5.5 保障性

(1)系统测试性要求符合GJB 3872《装备综合保障通用要求》的相关规定;

(2)具有使用维护说明书、操作使用教程,有醒目的使用和操作提示;

(3)常用易损件、耗材配备齐全,装备资料的完整性。

5.6 安全性

(1)应符合GJB/Z 99《系统安全工程手册》和GJB900A-2012《装备安全性工作通用要求》的有关要求。

(2)具有电源极性反接保护、接插件防插错功能;

(3)电气系统的绝缘电阻、介电强度满足GJB-1777-1999《军用专用汽车通用规范》的相关要求。

5.7 电磁兼容性

机构具有自兼容性,满足GJB 151B-2013《军用设备和分系统电磁发射和敏感度要求与测量》中对陆军地面设备的相关要求(含CE102、CS101、CS114、CS115、CS116、RE102、RS103)。

5.8 人机工程

应符合GJB2873-97《军事装备和设施的人机工程设计准则》的有关要求。

6 自主可控要求

根据装备国产化自主可控要求,本产品不允许使用进口元器件;

| 名称 | 规格/型号 | 单位 | 数量 | 备注 |

|---|---|---|---|---|

| 机构 | ||||

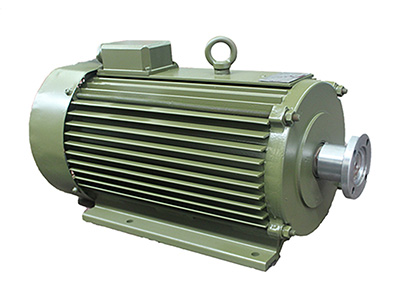

| 20KW驻车取力发电机 | SCT24-3-ZC | 台 | 1 | 3相AC400V |

| 25KW单相转换装置 | S25C400-220-K | 台 | 1 | 输出AC220V |

| 转速控制单元 | SCT-1500K | 套 | 1 | 安装于驾驶室 |

| 取力发电传动装置 | SCT-PTO | 套 | 1 | 安装于底盘 |

| 传动轴 | 长度按实际情况 | 根 | 1 | |

| 发动机提速装置 | 按键式、24V制式 | 套 | 1 | 定制,如底盘出厂刷好程序可取消 |

| 安装支架 | 套 | 1 | 定制 | |

| 标准件 | 12.9级 | 套 | 1 | |

| 电缆 | 耐高温搪锡硅胶软线 | 套 | 1 | 25平方 |

| 随装资料 | ||||

| 合格证明 | 份 | 1 | ||

| 随装工具、备附件 | 套 | 1 | ||

| 使用说明书 | 套 | 1 | ||